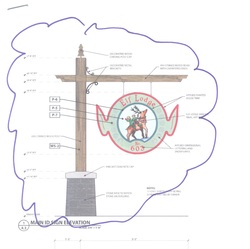

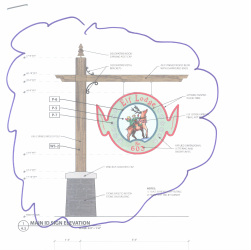

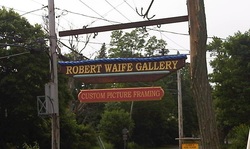

This image shows the overall sign concept.

This blog post is focused on the circular sign itself.

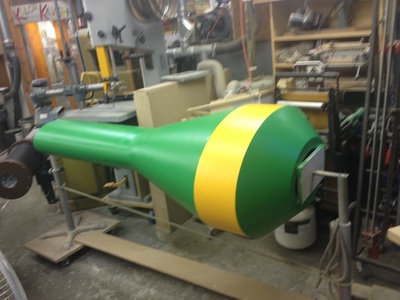

This sign is a total of 4" thick and 50" ear to ear.

you can see the basic shapes as they are exposed from this block of foam.

I delivered this sign before Santa's Village was ready to set it up, therefore I need to get up there and take some good pictures of it in place.

RSS Feed

RSS Feed